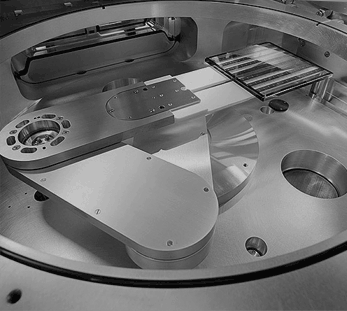

MASK ETCHER® SERIES

Plasma-Therm has pioneered dry etching for the highly specialized photomask market for more than 15 years. Mask Etcher® systems set dry etch performance and flexibility standards for photomask production. Plasma-Therm’s Mask Etcher® solution is a key enabler of Moore’s law and shrinking technology nodes. A wide variety of films can be etched from entry level 250um technology to < 32nm production with ICP high density plasma etch systems. Excellent uniformity and particle control are achieved through innovative technologies while maintaining high system production uptime. Plasma-Therm’s latest Generation V Mask Etcher excels in CD uniformity and linearity well below 5 nm.

Mask Etcher 2-V Evolution |

||||||||||

|

Hardware

- Dedicated platform specifically built for the highly specialized photomask market

- Several front-end handling options: - Ballroom/Bulkhead mounting - Automated load station (ALS) - SMIF on Automated Frond End (AFE)

Endpoint

Integrated multifunctional endpoint capability with EndpointWorks- Laser Interferometry

- OES

- System Parameters

- Custom input (e.g. RGA)

Software

- User friendly SEMI standard interface

- Comprehensive data logging

- Real-time process data display

- Fully integrated endpoint system

- Factory automation compatible (SECS/GEM)

- Multiple user access levels

- Alarm history

Process

-

- Compensation for uniformity and loading effect

- Low etch bias

- Good feature fidelity

- Low particle and defect

- Low line edge roughness

- Maximized productivity and low cost of ownership